Pipetector effectiveness is tested are evaluated through water sampling, filtering and cutting steel pipe pre and post installation. The below are some examples.

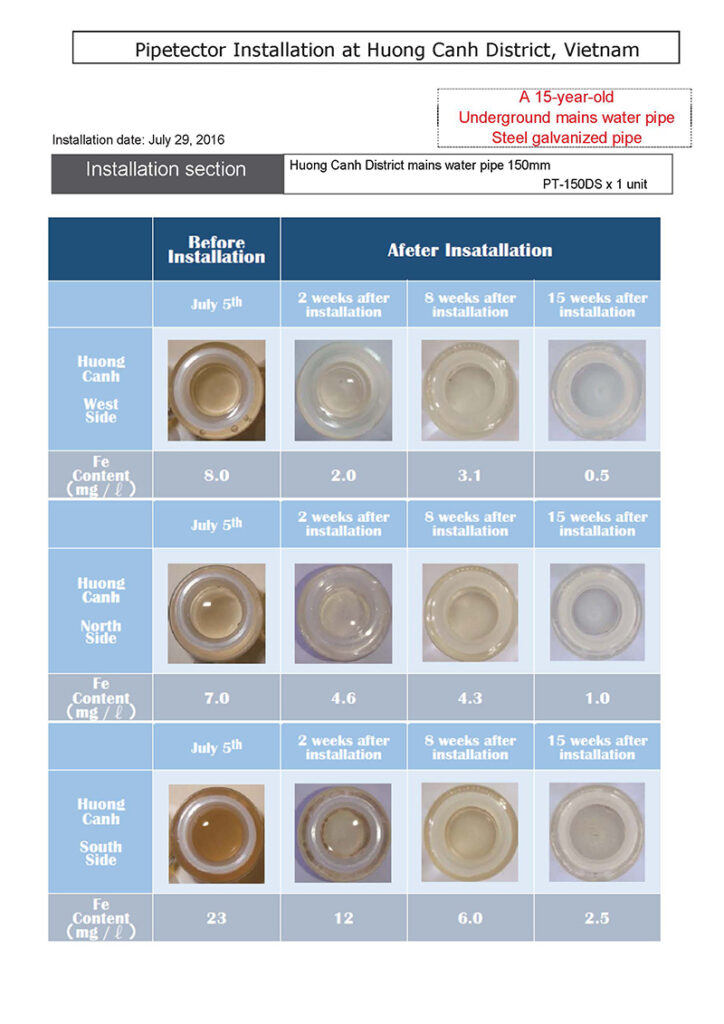

Discolored water became clear after the installation of Pipetector

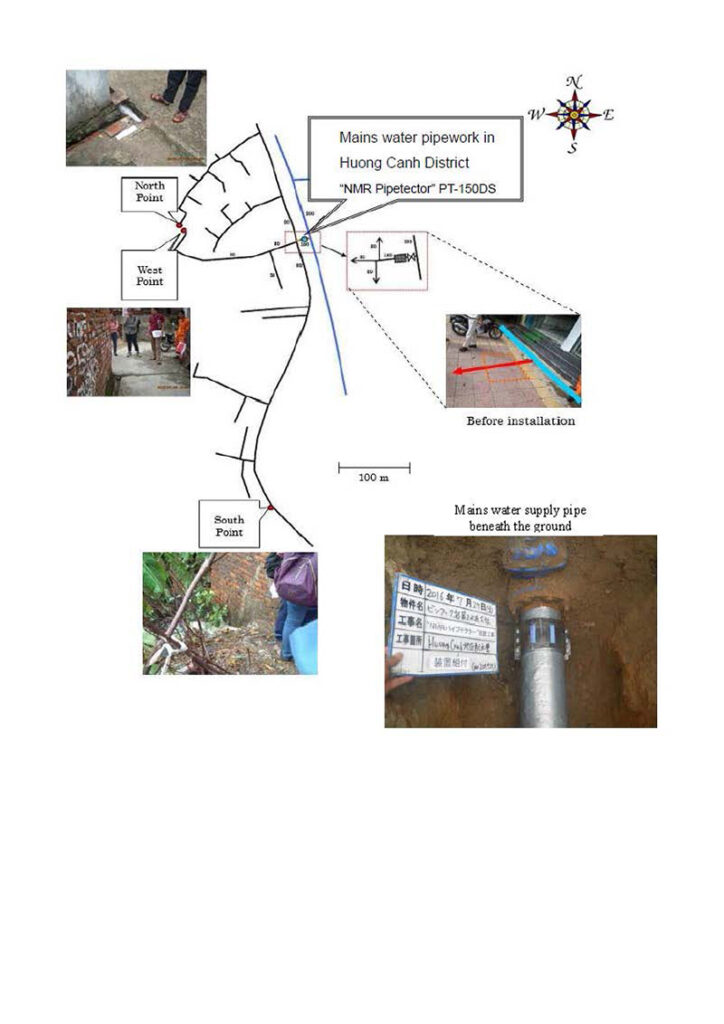

We tested our device Pipetector’s effectiveness on rusty pipes in July 2016 to confirm its potential for future ODA projects mainly in Southeast Asia among other developing countries. We sampled water from three spots of a steel water pipe before installation. Iron contents were 7.0, 8.0 and 23.0㎎/ℓ, indicating that internal corrosion was progressing seriously. However, 15 weeks after the installation, the level of iron content dropped to 1.5, 0.5, and 2.5 ㎎/ℓ each, and discoloration of water due to internal red rust became crystal clear. We now expect that the installed Pipetector will reduce the iron contents in water to the level of Japanese water quality standard, which is set at 0.2 ㎎/ℓ.

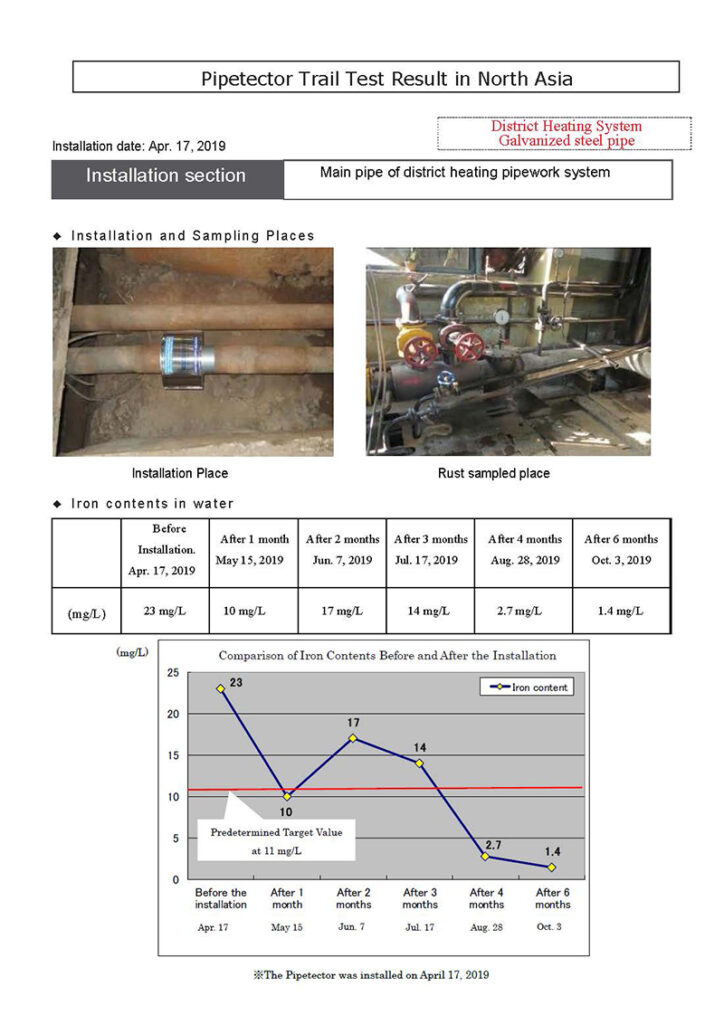

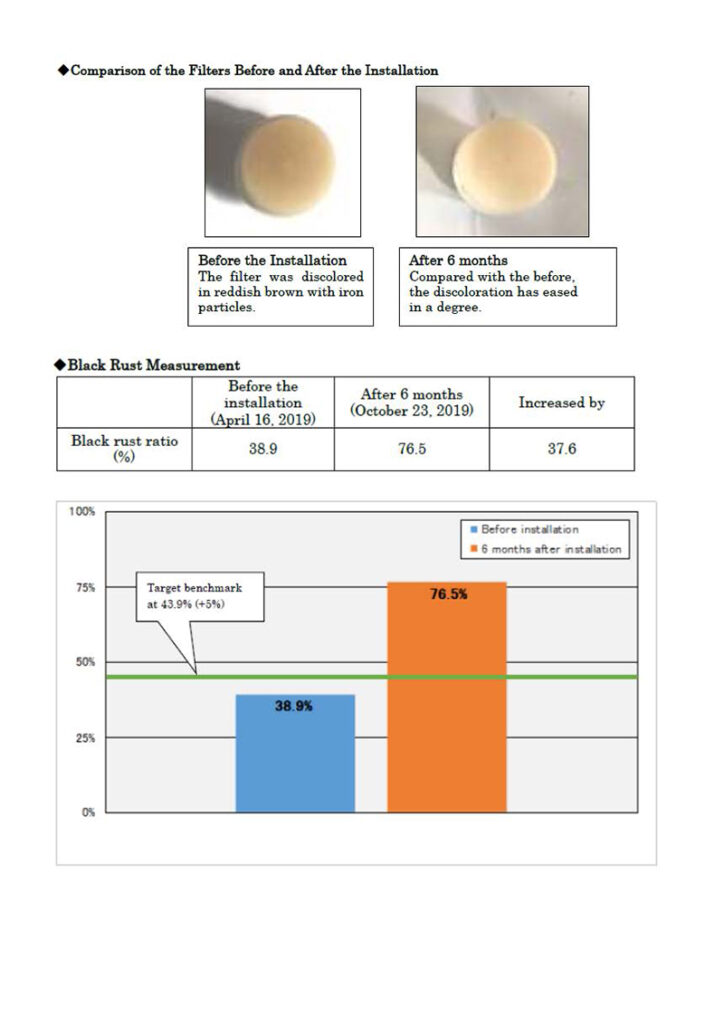

The effect of Pipetector was verified with filtering and cutting steel pipe

We installed Pipetector on the steel water main in a 3-mile district heating system on Apr. 2019. To determine the effectiveness of the device, we carried out two-tier procedures: filtering and testing of black rust ratio to total rust. Before the installation, iron particles captured in a filter showed a very high level of iron content at 23.0 ㎎/ℓ, but after 6 months, iron content was reduced drastically to 1.4 ㎎/ℓ. The black rust ratio to total rust was 38.9% before the installation but increased to 76.5% after 6 months. These results proved that Pipetetor prevented further formation of red rust and converted existing red rust to black rust.