Pipetector was installed on the outlet pipe of elevated tank at the photo service factory building in November 2000.

It has been 35 years since this building was built, and since the water supply pipe was made of Steel Galvanized Pipe (SGP), it was suffering from red colored water.

Other methods such as magnet, electric power, and ceramics can wash off corrosion developed inside pipework to worsen the water quality; it badly affects the quality of pictures which is not good for DPE business.

Pipetector which reduces corrosion to magnetite without washing it off was installed.

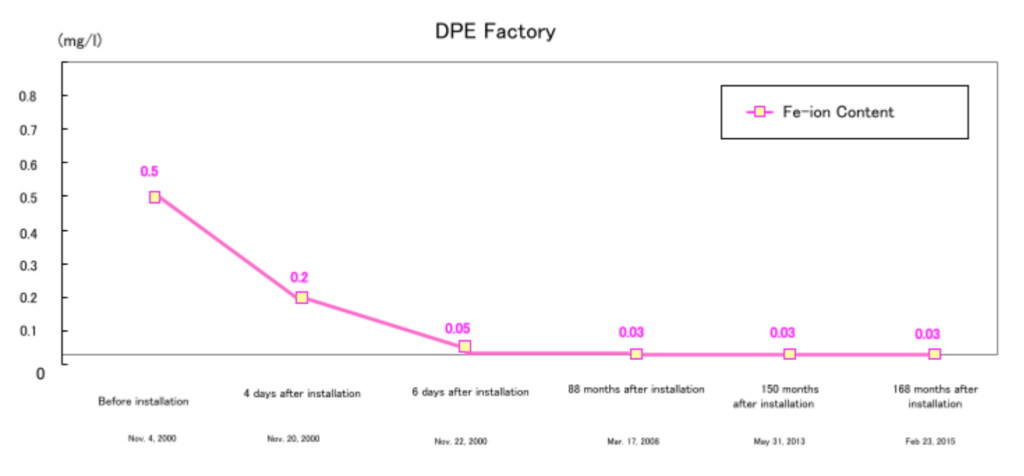

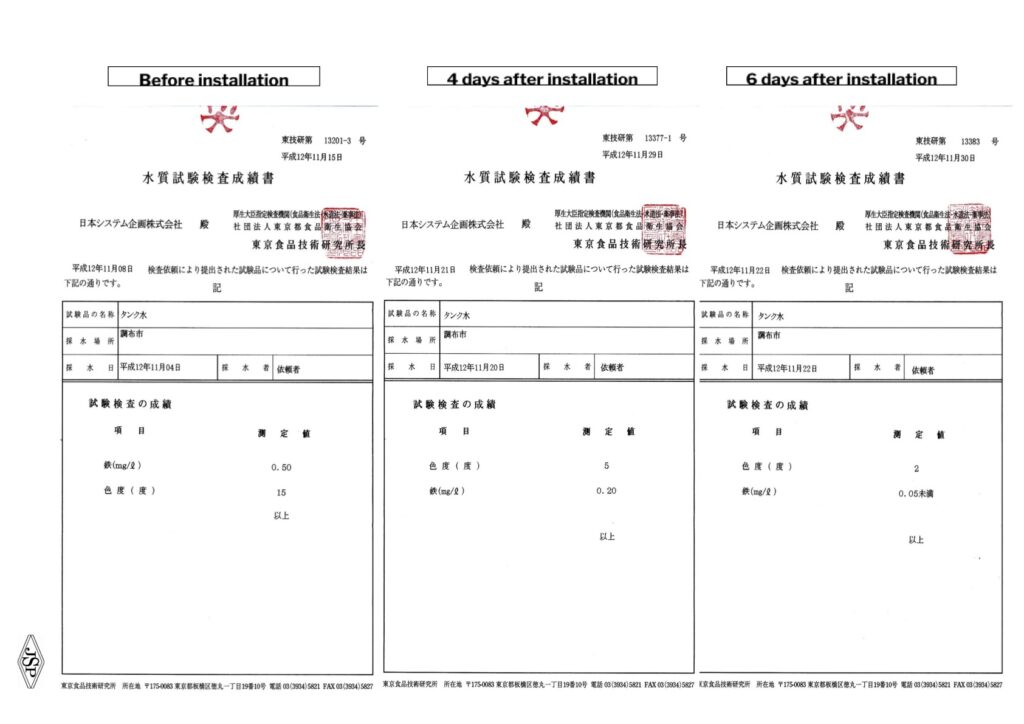

Before the installation of Pipetector, Fe-ion content of water in the morning was 0.5 mg/l and its discoloration was 15 degrees.

However, 6 days after the installation , Fe-ion content and discoloration decreased to 0.05 mg/l and 2 degrees respectively.

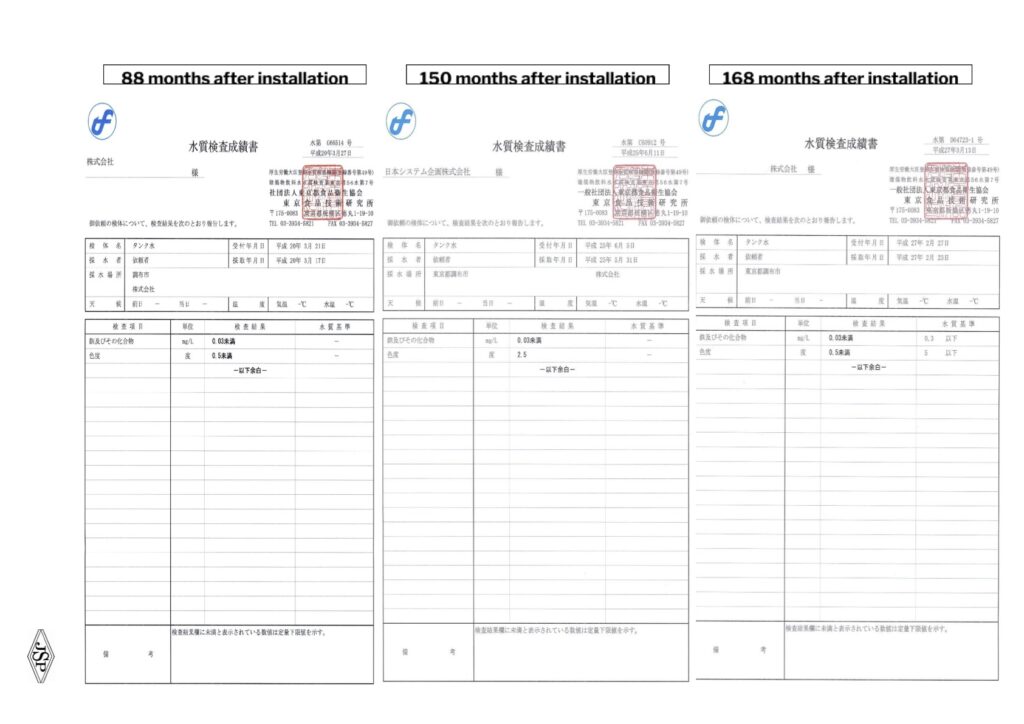

150 months after installation, Fe-ion content was less than 0.03 mg/l. These data show the outflow of corrosion completely stopped. Internal corrosion has not been outflowed since then.

Installation Summary

| Location | Chofu City, Tokyo, Japan |

|---|---|

| Building Summary | DPE Factory (35 years after construction) |

| Method of Water Supply | Supplied by elevated water tank Water consumption: 800t per day |

| Installation Day | November 16, 2000 |

| Installation Place and Number | Outlet pipe of elevated tank (SGP, 200mm in diameter) PIPETECTOR PT- 200DS×1 unit |

Fe-ion Content in Water

| | Before installation Nov. 4, 2000 | 4 days after installation Nov. 20, 2000 | 6 days after installation Nov. 22,2000 | 88 months after installation Mar. 17, 2008 | 150 months after installation May 31, 2013 | 168 months after installation Feb 23, 2015 | Governmen t Regulation in Japan |

| Fe ion Content in Water (mg/l) | 0.5 | 0.2 | Less than 0.05 | Less Than 0.03 | Less than 0.03 | Less than 0.03 | Less than 0.3 mg/l |

|---|