Comparing calcium scale deposit before-after installation

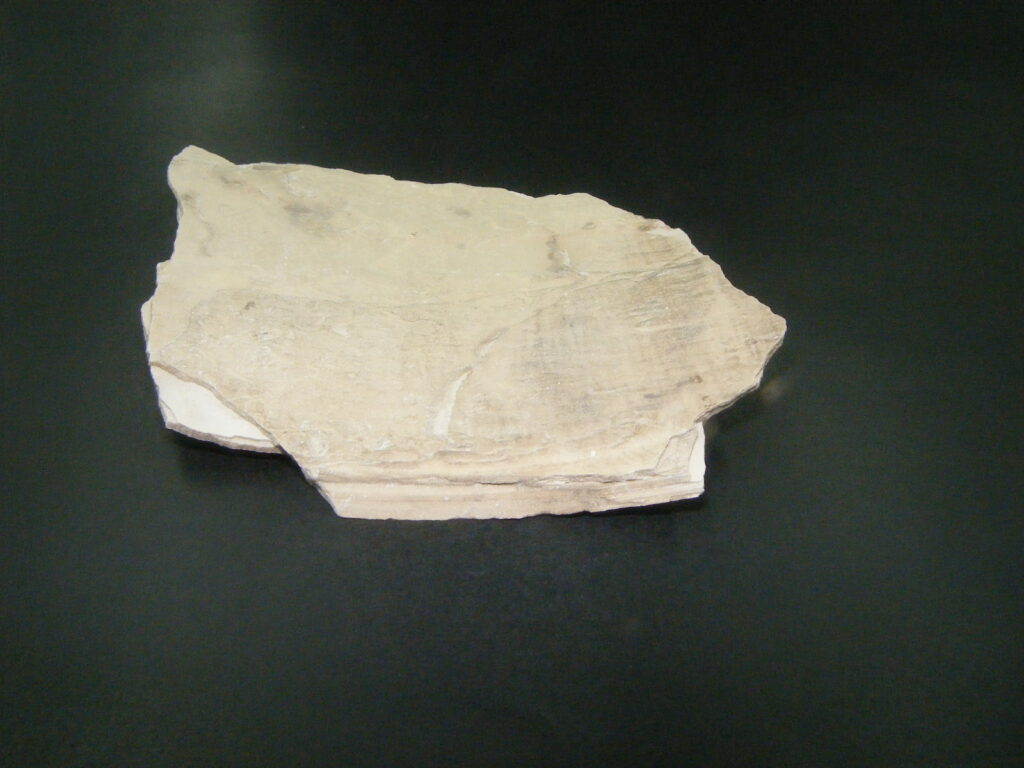

Solid scale deposit built up on the inner surface of the pump’s outer casing

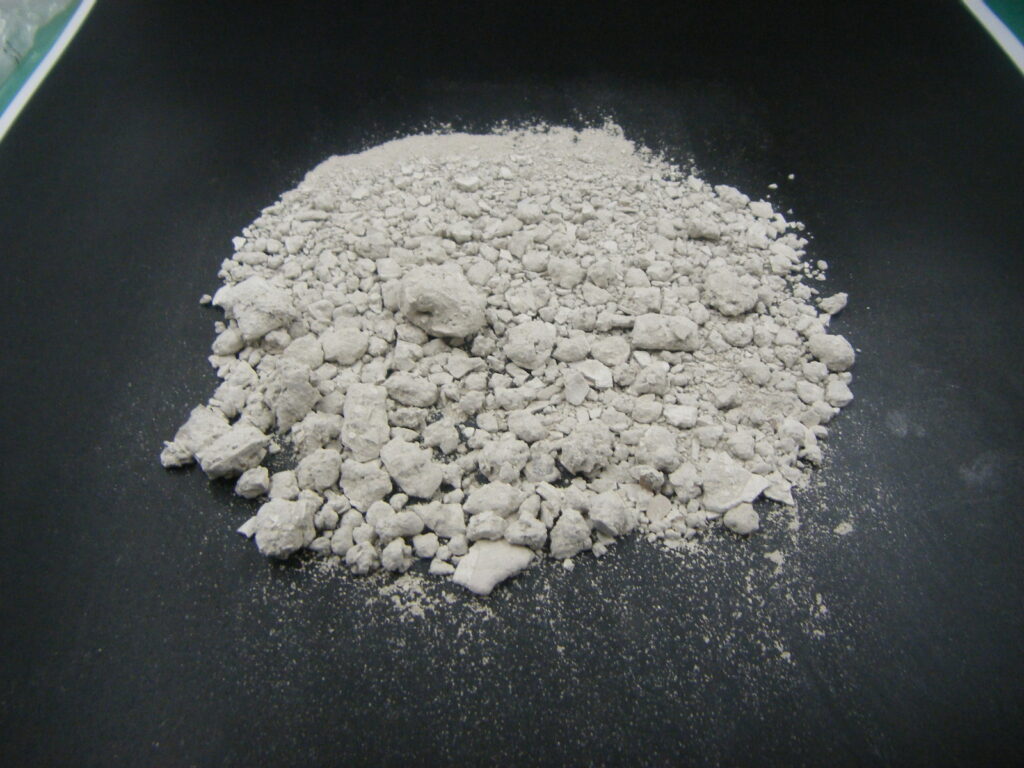

Scale deposit no longer be seen since it has become non-adhesive

Crystal particles of calcium carbonate built up inside the casing

Soft as powder, scale particles being reduced to a few millimeters in size

Overview

The steel factory was suffering from calcium scale built up on the outer casing of liquid ring vacuum pumps. Because of that, the pump impellers were damaged, ending up in frequent pump malfunction. The scale deposit had also disrupted the factory’s manufacturing lines for more than 20 times a year due to the loss in the vacuum pump suction.

To address these issues, the factory decided to use calcium scale softening device Non-Scalor. After newly replacing one of the vacuum pumps, the factory installed a Non-Scalor unit and observed how the device would deal with the deposited calcium scale for a period of six months as a test trial.

Six months later, the factory reported it had experienced no disruption on the production lines during the trial. In addition, the scale deposit built up on the outer casing was easily peeled off with fingers when the factory examined the inside. The hard calcium scale was converted into soft and ultrafine calcium particles. In conclusion, Non-Scalor has accomplished in protecting the pump impellers from being damaged by stiff calcium scale and maintaining the pump suction ability.

Details

| Test site | Steel manufacturing factory in Chiba Prefecture, Japan |

|---|---|

| Test purpose | Soften the calcium scale deposit on liquid ring vacuum pumps’ outer casing to protect vacuum pump impellers. |

| Test period | Six months from Nov. 2012 to May 2013 |

| Non-Scalor location | On a condenser water main flow pipe connected to three liquid ring vacuum pumps |