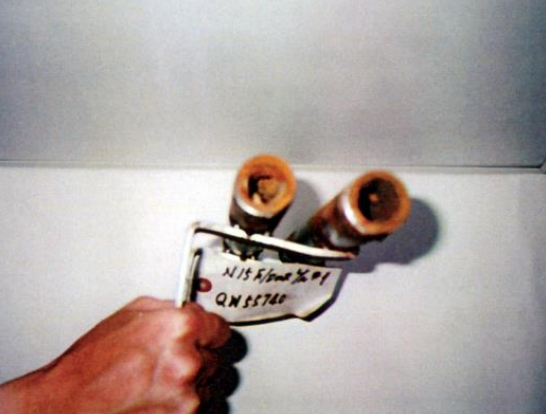

Before the installation

Inside of the cooling water pipe was seriously blockaded caused by corrosion. Therefore, the clogged cooling water pipe for the welding robot stopped the whole production line often.

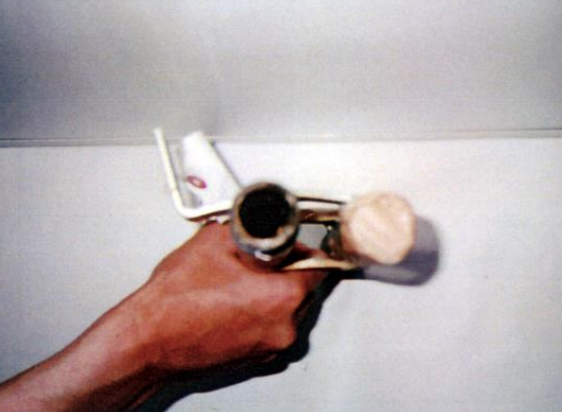

9 months after the installation

The corrosion was reduced to magnetite

and clogs of the cooling water pipe disappeared. So, the whole production line did not have to be stopped.

Color

The rust before the installation of PIPETECTOR was red color.

The rust taken 9 months after the installation of PIPETECTOR became and formed

magnetite film covering the inner pipe.

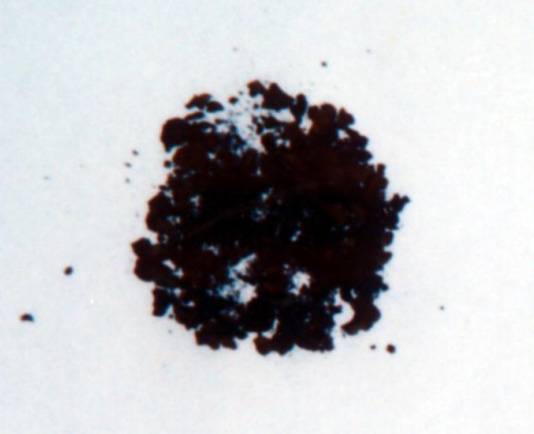

Analysis of Mass Magnetite

According to the analysis done by Tokyo University of Science, before the installation of

PIPETECTOR, the ratio of magnetite as 4% while corrosion was 96%, but 9 months after

the installation, magnetite became 43.6%. It proves that corrosion was reduced to

magnetite which became film and protected the pipe.

Installation Summary

| Method of Water Supply | Circulation water method |

|---|---|

| Installation Day | August in 1998 |

| Installation Place Number of Installed PIPETECTOR | On cooling and circulation water pipe (SGP 30mm in diameter) PIPETECTOR PT- 30DS×4 units |

Economical Profit by the Installation of Pipetector

The following economical profit was found after the installation of

Pipetector, the corrosion which clogged the cooling water pipe was reduced to

magnetite, and decreased the clog.

- Increase of production because of the increased cooling effect and no stop of

operation by clogging the pipe. - Decrease of cost because of the unnecessary of stopping operation and decreased

maintenance fee. - Decrease of running cost because of the unnecessary of the use of Anti-corrosive

chemical.