Background

Today, we would like to introduce a case study at the British Museum, one of the most grandeur museums in the world. We have discussed how Pipetector was adopted and brought advantages there.

What kind of a museum is it?

The British Museum is an important cultural faciity that preserves and passes on the UK’s history to future generations. Located in London, it displays and stores eight million historical artifacts, books, and treasures collected from around the world. Some sections of the building, such as the Great Court built in 2000, went through reconstruction works, but others have remained untreated since their construction.

Problems

While the museum was partially refurbished, some facilities were not treated, but have been used until nowadays since the museum was first opened to the public. The sections, especially those not visible from the outside such as piping, had deteriorated in a not so long period as a result.

As the years had passed, the plumbing systems at the museum had severely deteriorated to the point one step away from breaking down. left untreated, it might have caused water leaks from pinholes all over the pipeline. This had posed a serious threat to the museum.

Generally, a major issue of rusting pipes is red rust, which leads to development of corrosion inside. Corrosion can cause water discoloration or pipes to break down in the worst-case scenario.

The British Museum was aiming to subside the influence stemming from the internal red rust to secure concrete preservation of its art collections. If the water lines would break and water leaked through pinholes, the damage to the collections could be immense.

To protect the valuable artifacts and keep them in a much safe state, the museum had to take care of the internal red rust inside its aged piping whatever it might cost.

Comparing with alternatives

Pipetector played a significant role in protecting the museum’s pipes. But how exactly did the museum utilize it? Actually, the museum was considering other ways to protect and prevent the plumbings from red-rust deterioration at first. The options were as follow:

- Pipe replacement

- Using a by-pass pipe filtering system

Replacing pipes is effective as it literally renews pipes themselves, but has disadvantages as well. It could cause disruption to the water supply during long-term replacement work. Because the museum also held restaurants and other stores, the impact on tourists would be devastating. The cost was way higher than Pipetector, too.

The other option, the bypass pipe filtering system, is a means by which installing a filter with a reverse osmosis membrane in pipes to prevent red rust from developing. However, since this type of system does not affect existing red rust, chemical dosing is then necessary to remove precipitated red rust.

But, once agian, the museum does not allow dosing chemicals due to their potential risks on exhibits. Also, they are ineffective on brittle pipes already damaged and require huge and regular maintenance costs. Compared with them, Pipetector was the best option in terms of cost and facility operation.

Effectiveness testing

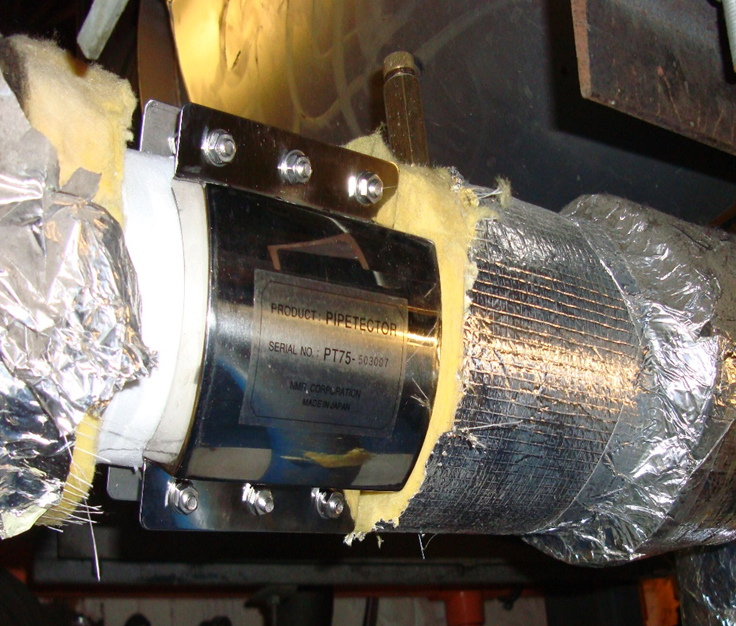

The museum installed Pipetector in its main heating water pipework providing hot water to Area F as a trial. After it was installed, the museum confirmed its effectiveness against red rust corrosion in five weeks.

In detail, the iron contents in the hot water declined from 20 mg/L to 0.2 mg/L, equivalent to a one-hundredth reduction. With this outcome, the museum confirmed the reduction of red rust to black rust, a substance that is insoluble in water.

0.2 mg/L is a level that we do not need to concern any risks of red rust whatsoever.

Strengthening aged pipes

Next, let us talk about black rust. Black rust is a substance completely different from red rust and beneficial to metallic products. It has been used as a protective coating of Japanese antique iron kettles, woks; and western steel locomotives.

Pipetector can take care of corroded pipes by coating their internal surface with the protection of black rust without ousting the existing red rust from pipes within. As existing red rust is gradually converted to black rust, the black rust “film” will keep forming and growing to the point that aged pipes are able to restore their integrity. As a result, the refurbishment of pipes can be accomplished without replacing them.

Free from red rust concerns

With Pipetector, pipes remain resistant to damage that comes from internal red rust. From now on, the museum can not just prevent the risks that would have been raised already, but also be free from risks in the future. No need for pipe replacement means no concern for shutting down the water supply or dosing chemicals that are destructive to exhibits.

Conclusion

The British Museum is in a sensitive environment because of its many valuable collections. Its plumbing system had to be renewed without cutting off the water supply or halting the museum operation. The museum chose Pipetector as the best way among various options because of its cost merit and the advantage to strengthen pipes without replacement. We recommend that any buildings that do not want to cease their operations or interrupt their water supply adopt Pipetector.