It has been 11years since the food factory was built, and High Impact Vinyl Pipes (HI-VP) have been used. The factory has used well water.

Generally, well water has more bacteria than tap water, and it causes to form and grow slime easily.

Pipetector was installed in order to prevent growing the bacteria in the cooling tower of the food factory.

As the result, algae of the cooling tower stops growing because of the effect of Pipetector.

Before the installation of Pipetector, the number of single cell bacteria was 640, and colored from organic dirt was 8 degrees.

4 weeks after the installation, the single cell bacteria decreased to 270 and colored decreased to 3 degrees. The consumption of potassium permanganate (KMnO4) decreased from 13.3 mg/l to 11.4 mg/l, remains after evaporation of water decreased from 952 mg/l to 499 mg/l, nitrogen nitrous acid from decreased 13.2 mg/l to 4.7 mg/l.

The water examination proves that the water treated by Pipetector improved the quality of water a lot.

Installation Summary

| Location | Shizuoka prefecture, Japan |

|---|---|

| Building profile | Factory (11 years after construction) |

| Installation date | October 30, 1998 |

| Installation pipes | On inlet of well water pump (HI-VP 40mm) PIPETECTOR PT- 50DS×1unit |

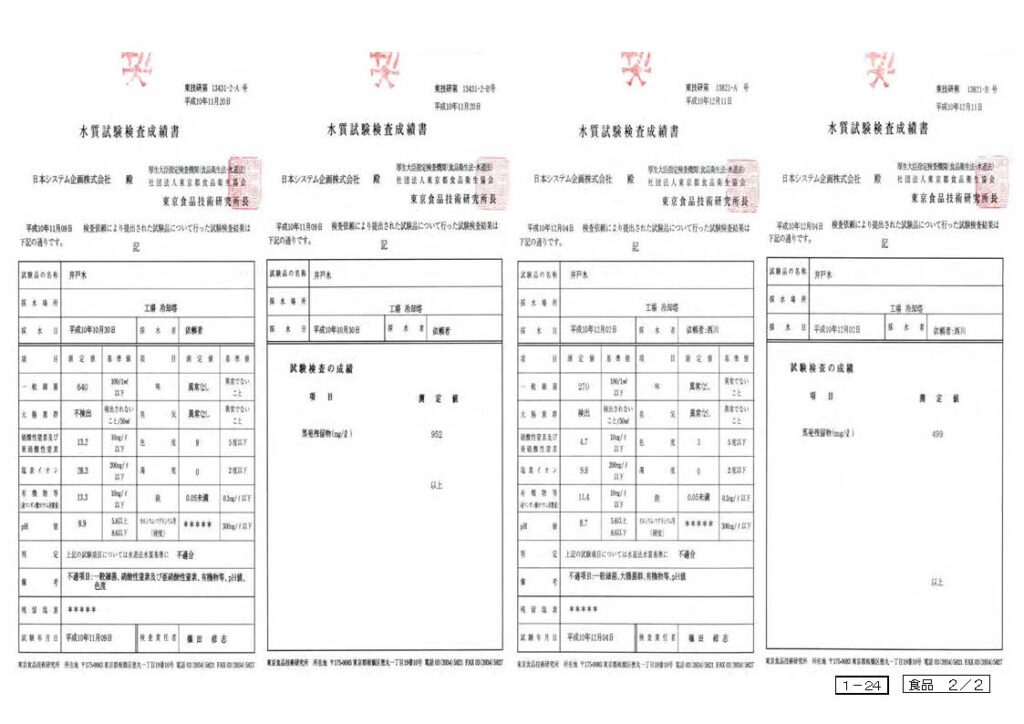

Water Quality Test Results

| Item | Before installation | After 4 weeks |

|---|---|---|

| Single cell bacteria | 640 | 270 |

| Nitrogen nitrous acid (mg/l) [No3-No2-] | 13.2 | 4.7 |

| Chlorine ion (mg/l) | 28.3 | 9.8 |

| Potassium permanganate KMn4(mg/l) | 13.3 | 11.4 |

| Colored (degree) | 8 | 3 |

| Remains after evaporation of water(㎎/ℓ) | 952 | 499 |