The wire rod factory uses a centrifuge to separate oil-water emulsion, which is used in the process of manufacturing. The separated water is then discharged as wastewater.

However, soon after the factory started using the centrifugal device, it caused frequent malfunctions that affected the factory’s operation. When factory engineers checked the apparatus, a hard scale was built up on the centrifuge’s turbines, which was likely the cause of the equipment failure.

In general, the solubility of dissolved calcium ions drops when heat or water pressure rises in water pipes. A hard calcium carbonate scale tends to build up within such plumbing systems.

The turbines heat up to 70-90 degrees Celsius during operation. The factory hoped they could prevent unexpected machine failure if the growth of the calcium scale was controlled.

Therefore, the factory conducted a test trial of Non-Scalor to see how it worked against the scale.

Before the factory installed Non-Scalor, the centrifuge had stopped about once every other month. The engineers had to repair and clean the broken diffusion machine for three days. However, after the Non-Scalor installation, the centrifuge kept working without halting for four months at the same frequency of use as before installation. The appearance of the scale also changed; The thick scale layer that the engineers had to remove with spatula tools before installing NS was eliminated when they disassembled the centrifuge to see the scale adhesion four months after the NS installation. From this test trial result, the factory confirmed that Non-Scalor successfully inhibited calcium scale formation, which then led to preventing machine failure. The factory is now free from any unexpected suspension of the facility’s production.

Installation Summary

| Facility | Major steel company’s wire rod factory in the Kanto region, Japan |

|---|---|

| Target | A centrifuge at the wire rod factory |

| Centrifuge age | About a year |

| Installed date | Jun. 26, 2018, by Japan System Planning Co. |

| Installed spot | The #2 C2 pipework system supplying oil-water emulsion to the centrifuge |

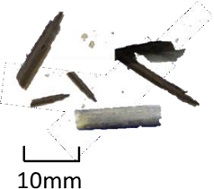

Sampled scale

Before installation

Sampling after 60 operation days

Scale (left photo) being built up on the centrifuge turbines, causing machine failure.

Four months after installation

Sampling after 120 operation days

The adhesive scale on the turbines was drastically reduced;

the hard scale turned into soft particles

Centrifuge turbines

Before installation

Sampling after 60 operation days

Scale adhering to build up a thick layer

Four months after installation

Sampling after 120 operation a days

The scale adhesion that was seen before the NS installation was gone.

What remained was soft particles easily removed by hand.