Use your pipes for a longer period

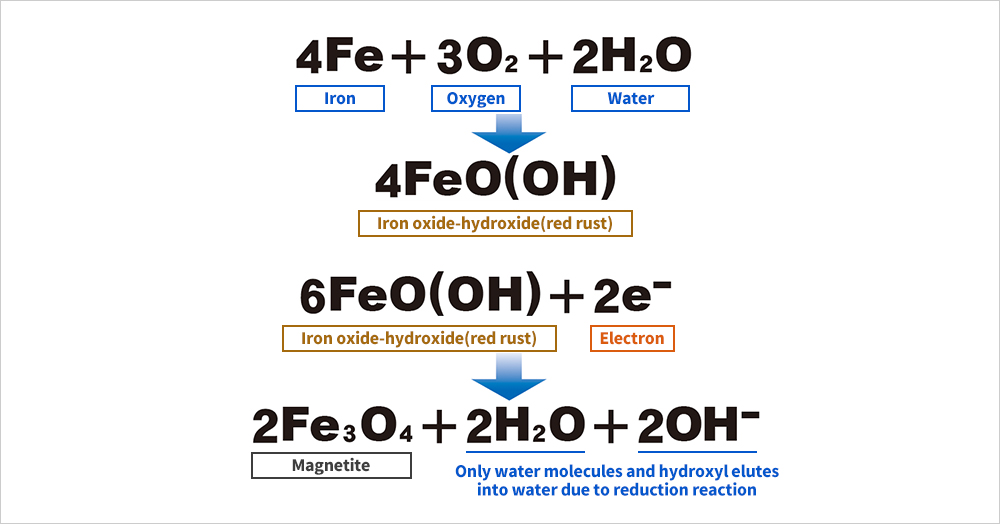

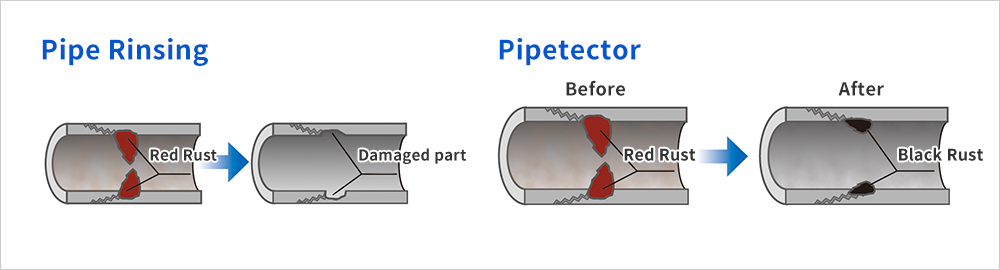

Pipetector extends the life expectancy of old pipes as long as that of buildings by changing internal red rust to black rust, a water-insoluble substance. With this, you do not have to go through pipe replacement that causes CO2 emissions when constructing new ones.

Extending lifespan of pipes for over 40 years

Steel pipes can be used for about 20 years in general. However, Pipetector allows us to use the pipes for more than 40 years without being bothered by corrosion. In fact, Pipetector has many case studies to support this. For example, the Teigeki building and a major DPE factory have used their pipes for 55 years; the Yaesu Guchi Kaikan building has used its pipe for 56 years.

Black rust does not dissolve in water and has a hard lattice structure with a volume smaller than 1/10 of that of red rust.

Because black rust is corrosion-resistant and forms a dense coating to cover the surface of metals, it is used to protect the surface of iron products such as woks and steam locomotives from rusting. It has also been used for nails and hinges made way back in the Nara and Heian periods (between 710 and 1185), protecting the iron products from corrosion deterioration for centuries.

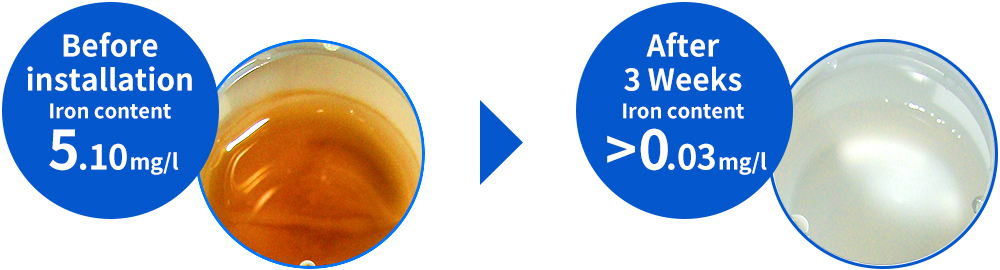

Converting red rust to black rust, Pipetector stops the elution of iron ions, leading to the clearing of water discoloration. Eventually, Pipetector removes the blockage caused by red rust, as black rust has a smaller volume than red rust has.

Cost comparison: Pipetector v.s. pipe replacement

Once you install Pipetector on your old pipes, you will no longer need to replace them. Pipetector costs less than 1/10 of pipe replacement does on average and thus saves facility maintenance cost. The following images describe the actual cost merit of Pipetector.

Royal Garden Hotel London, UK

The total Pipetector cost was £100 thousand at the hotel, while it could have cost £6.5 to 7 million (£1 = ¥140) if the hotel were to choose pipe replacement. The hotel achieved to cut its facility cost to 1/65~1/70 in the end.

Realizing zero maintenance cost for pipes

Pipetector does not require maintenance, monthly electricity cost, or cause damage to pipes at all. On the contrary, those pipes gradually gain thickness as Pipetector forms a layer of black rust on the pipe inner surface; in other words, pipes’ structural integrity increases.

Increasing property value

Pipetector largely reduces building maintenance costs, allowing apartments to gain financial leeway in their operating budget. In fact, many buildings have succeeded in improving their asset value through various renovations, such as installing a new elevator, repainting outer walls and waterproofing roofs.

No pipe cutting or disrupting water supply

In general, it costs us extra expense to shut off the water supply during pipe replacement works, in addition to the cost of the work itself. Other conventional methods to deal with rusty pipes may require cutting them.

In contrast, we can install Pipetector by just attaching it around a pipe with a couple of screws. You do not have to cut pipes or turn off water infrastructure; thus, it only takes an hour or two to install the device. It is beneficial at hotels and hospitals, particularly where you cannot shut off the water supply for patients and hotel guests.

*Any installation on underground water mains takes extra time to dig the ground and restore it to its original state.

Safe and hygienic

Does not be in contact with water

As Pipetector is fitted on the outer surface of pipes, it does not directly contact the water flowing inside pipes throughout the product’s minimum lifespan of 40 years, thus hygienic. Pipetector has gained many reputations for that advantage.

Improves pipe integrity, no chemicals used

Conventional methods pose a safety risk on tubing, as they require chemical dosing to water and wear off the thickness of pipes when washing inside the lines. Pipetector, as it only needs to be fitted on the outer surface of pipes, does not be in direct contact with water. For this reason, you do not have to dose chemicals or have a fear of damaging your pipes.

Disadvantages of conventional plumbing methods

To replace pipes is the most costly way to address corrosion issues in your pipes. You also have to shut off the water supply, deal with waste materials and a mass amount of CO2, being adversaries to SDGs.

Red rust corrosion still grows at pipe joints where you cannot physically implement a coating treatment. Moreover, there is an increased risk of developing cancer if epoxy resin, a carcinogenic substance, elutes in drinking water.

Wrapping electrode cable around pipes is limited to scale deposits, not for corrosion.

More than 150 Japanese companies have supplied magnetic devices for the past 3 decades, but none of them was able to show evidence they could prevent corrosion in pipes. As a result, most of those suppliers had to suspend business operations.

Total solution to red rust-relating corrosion

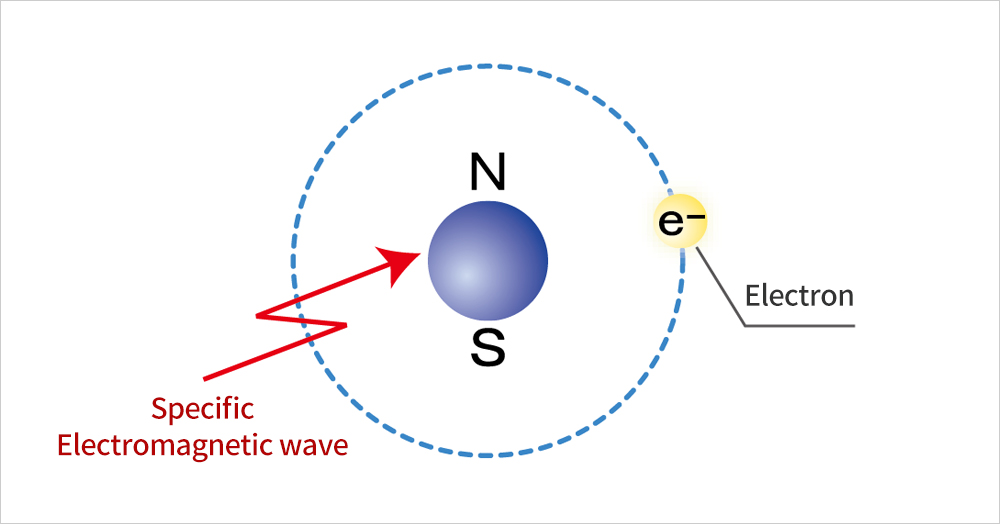

Pipetector contains black-body substances formed in the process of sintering 12 types of rare metals. This allows the device to emit electromagnetic waves at a certain frequency towards water pipes. We tested and proved that those waves did not affect the human body in an exam* at Chemicals Evaluation and Research Institute, Japan.

As shown in the testing, the electromagnetic waves generated by the device are weaker than those of home appliances, including cell phones. However, because the safety of the waves is guaranteed as they neither affect cardiac pacemakers or other medical machinery, many Japanese hospitals have adopted Pipetector to their pipework.

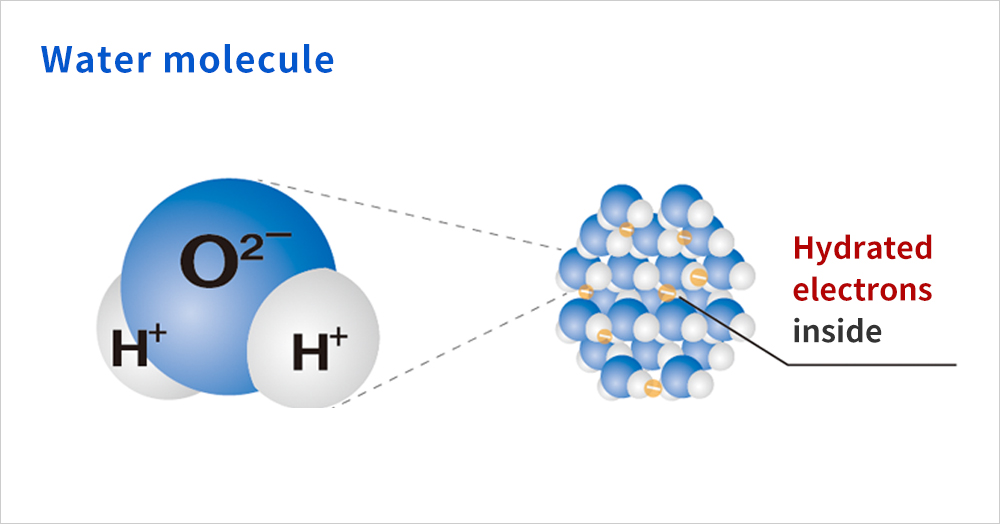

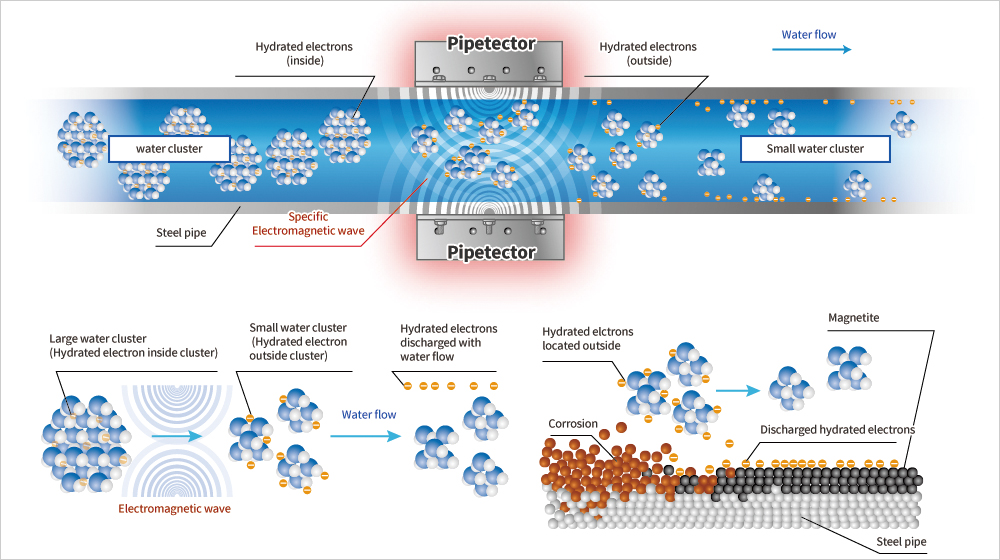

The mechanism of the device is this: 1. electromagnetic waves relocate hydrated electrons inside water clusters to their outer surface. 2. the hydrated electrons are then emitted as water flows inside pipes. 3. The emitted electrons adhere to red rust inside pipes, reducing it to black rust.

*Click here to see the test report by Chemicals Evaluation and Research Institute, Japan

Water molecules in water are aggregated into a large mass called a water cluster. Hydrated electrons, one of the key elements of rust reduction, exist in a water cluster of a group of 64 water molecules or more. Without Pipetector, hydrated electrons are kept inside those water clusters.

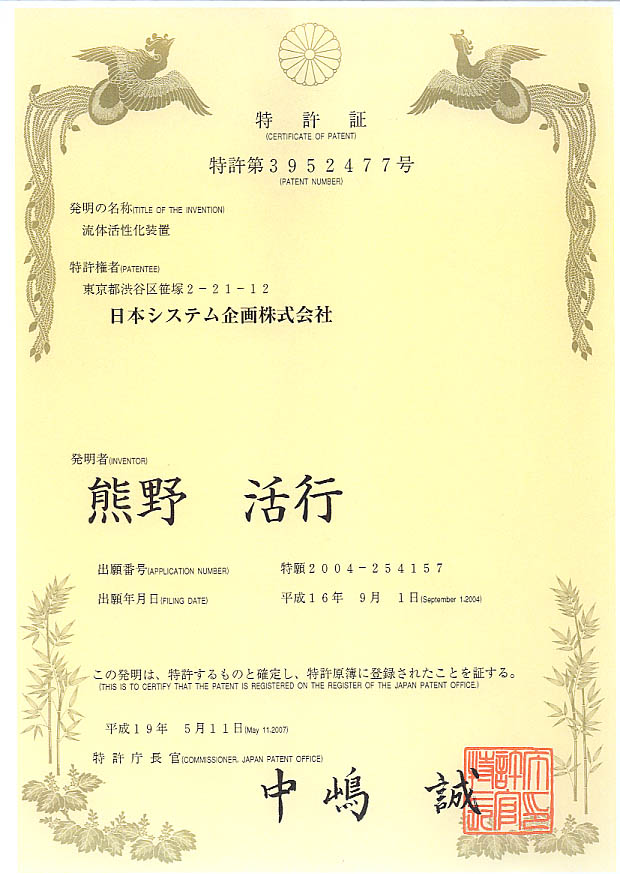

Worldwide-patented technology

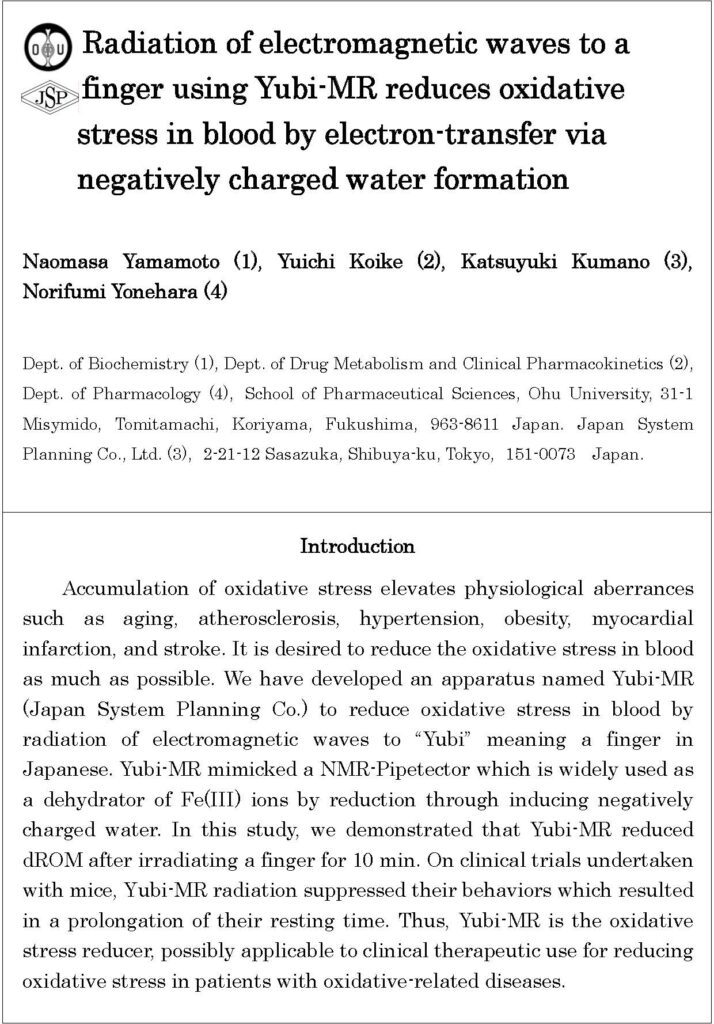

Treatises accepted by international academic meetings

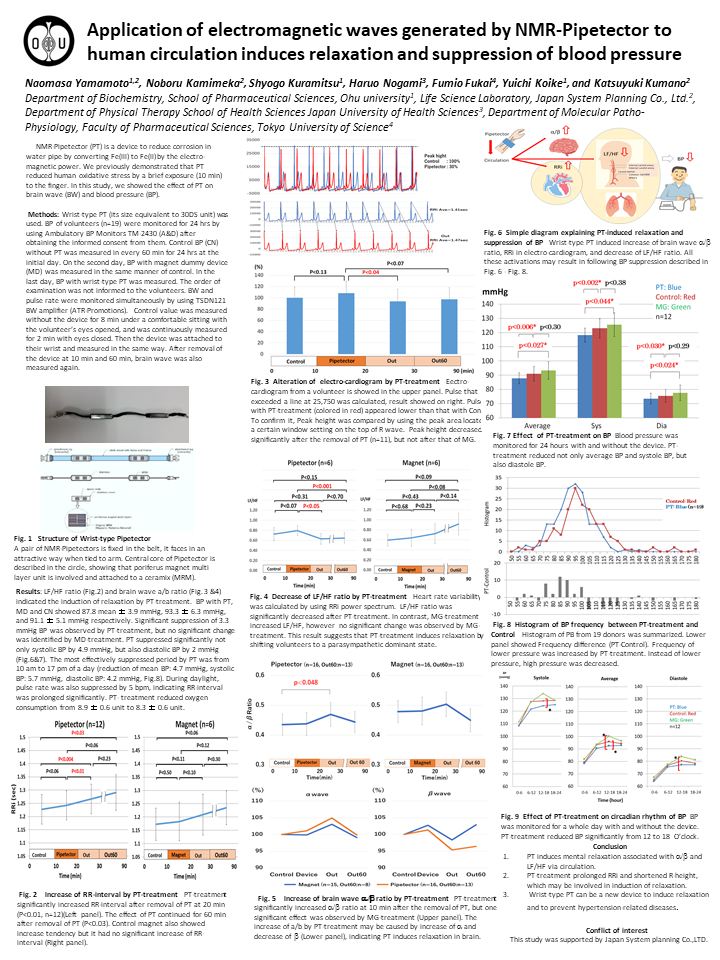

Three symposiums duly accepted our treatises on the NMR technology. It was the first academic conference ever to accept a paper focused on the technology extending the life expectancy of metallic pipes.

Those research groups are the 13th Asian-Pacific Corrosion Control Conference, the Japan Association of Corrosion Control conference 2005, and the World Pharmaceutical Congress 2010.

Applicable to any kinds of pipe systems, buildings

Pipetector can be used for any type of building. In fact, it is used at apartments, flats, condos, hotels, inns, hospitals, nursing care facilities, commercial facilities, public facilities, factories, bank buildings, schools, office buildings and supermarkets.

Pipetector also fits in with various pipe systems, such as domestic tap, hot, air-conditioning heating, chilled, condenser water pipes and underground water mains.

Pipetector also has many case studies abroad. In the UK, it is used in Buckingham Palace, the Guildhall in London, Palace of Westminster, the British Museum, a BBC building, Whittington Hospital, the Royal Garden Hotel London, the Royal Bank of Scotland, City, University of London and Harrods, among many other renowned buildings.

Client testimonials

Pipetector has acquired favorable reputations on its efficacy and benefits from our customers. We received client testimonials from the Royal Bank of Scotland, Royal Garden Hotel London, the Guildhall in central London and Whittington Hospital, one of the NHS Trust medical facilities.

An innovative device drawing attention of media

MANUFACTURING TECHNOLOGY INSIGHTS

A U.S. technical magazine Manufacturing Technology Insights selected Pipetector as one of the top 10 corrosion control technologies worldwide. The magazine also featured the achievement in its 2020 issue.

“PAPYRUS” in March 2025 Issue

Based on these results and the case study at the British Museum, the results show that the Device (Pipetector) can contribute to a sustainable era for museum operations in the U.S. and worldwide. (From an article of PAPYRUS, March 2025 issue)

The American journal PAPYRUS is a professional magazine about the management and operation of museums and other cultural facilities, published four times a year by the International Association of Museum Facility Administrators (IAMFA).

It introduces the latest facility management examples and discusses issues facing modern facility management, such as improving energy efficiency, making it a valuable source of information for professionals interested in facility management and cultural heritage protection.

Discovery Channel “Beyond Future”

A U.S. consumer-focused TV show News Watch TV on Feb. 12, 2016 featured Pipetector as a new technology holding great expectations. Another U.S. TV program Beyond Future, on Feb. 20 aired Pipetector in the same year as an innovative technology made in Japan.

Several trial options

Per the customer’s actual site conditions, we select the most suitable method for a test trial from one of the following: water sampling, filtering, and testing of black rust ratio.

Three ways of trial

* Testing period differs depending on customer’s site conditions and trial method

Verified the effectiveness at a third-party institute

We verified Pipetector’s effectiveness on old water pipes with the supervision of Hokkaido University Professor Emeritus Toshio Yuta at the former Hokkaido Industrious testing facility.

The iron level in water was 0.786 mg/L before installation, but it gradually decreased after a month, and after four months, it drastically dropped to 0.262 mg/L. This figure is below the iron level requirement at 0.3 mg/L determined in the Japanese drinking water act.

Agent/agency in charge of trial

A sales agent/agency either samples water or carries out a filtering test in witness of customers. The agent/agency then outsources the analysis of sampled water or a filter to a third-party lab as a part of a test trial.

Reference: a certificate of lab testing from the case study at Royal Garden Hotel London

Rectifies smell and taste of water

Pipetector largely improved the water quality of a condenser water system at an 11-year-old food processing factory in Shizuoka Prefecture, Japan. After installing Pipetector, the number of single-cell bacteria in the condenser water dropped to 270 from 640 per 1 mL. The level of watercolor, which rises as organic matter thrives, also dropped from 8 to 3, a figure within the Japanese water quality requirement.

Not only did the number of bacteria lessened, but the level of potassium permanganate also did: its consumption declined from 13.3 mg/L to 11.4 mg/L. Because Pipetector functioned as a total solution to rectify the water quality, the residue on evaporation also dropped to 499 mg/L from 952 mg/L. The level of nitrate-nitrogen, which also increases as organic matter grows in water, significantly sunk to 4.7 mg/L from 13.2 mg/L.

Pipetector kept suppressing the algae growth in a factory’s cooling tower even after the factory cut the chlorine dosage to the condenser system to 1/3.

10-year warranty

We offer every customer a free replacement for any defective product covered with a 10-year warranty. This warranty is in effect from the day Pipetector is installed.

Maintenance-free

Pipetector saves costs of facility maintenance because it is totally maintenance-free once installed.

Free testing inside your pipes

To assess the degree of corrosion development inside your piping, your agency proposes a pre-exam, such as site survey and water sampling, before installing Pipetector to ensure that the device can actually solve the issues.

Points of attention

- Buildings need to have a certain daily water consumption: e.g., around 100-200 mL a day per tap.

* If water consumption is smaller than 100 mg/L a day, it might take 3 to 6 months for Pipetector to be effective. - Pipetector deals with internal corrosion stemming from red rust inside pipes, as the reducibility is limited to places where water flows.

- Although Pipetector can stop the development of new copper corrosion in copper pipes, any existing copper corrosion, i.g. verdigris, cannot be reduced to an insoluble substance, such as magnetite, as there is no such substance for copper.

Our history

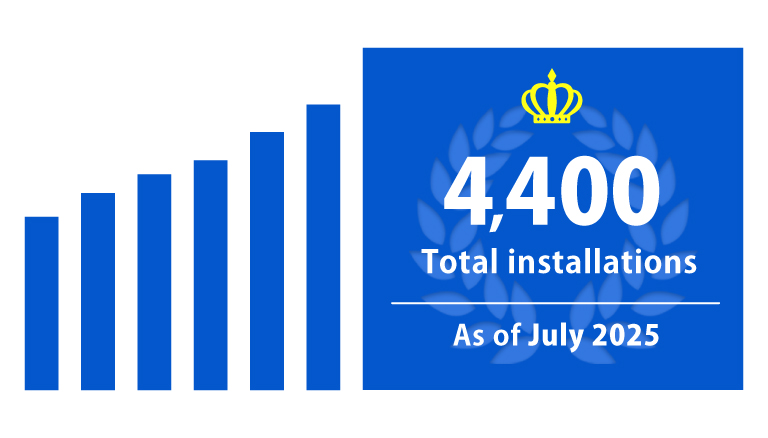

Japan System Planning Co., Ltd. manufactures and markets Pipetector, a proprietary device designed to prevent corrosion in aging water pipes. To date, it has been installed in over 4,400 buildings across Japan and in numerous buildings overseas.

Taking actions for the Sustainable Developmental Goals

Established in 1988, our company endeavors to contribute to a sustainable society with its own patented technology. Making pipe replacement works unnecessary; the technology can save the energy for making new pipes and reduce waste materials that come from such works.

With a vision of providing eco- and health-friendly products to society, we are committed to achieving the SDGs even further.